|

|

You are here:  Home > Application Center > Technology Articles Home > Application Center > Technology Articles |

|

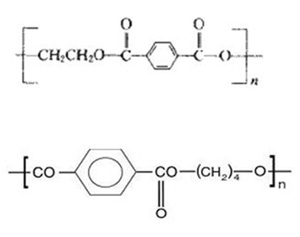

1. The properties and application of modified PET

PET is the most cost-effective answer when we intend to consider the materials, which combine the stiffness, high temperature performance, better dimension stability and high gloss. It has the reinforced polyethylene terephthalate (PET) for optimum performance and easy processing, which can produce high performance parts according to the traditional forming methods:

1) The deformation temperature is 20 ?C higher than modified PBT, and it can be processed in a wide range of temperature;

2) PET components can maintain the performance and size because of its low water absorption rate. That makes it to replace the die cast metal and thermosetting plastic, PA in the key requirements of stiffness, the critical tolerances and decoration parts. PET, with its excellent flowability, allows it to be used in lower injection pressure than other resins filled with complex, thin-walled mold. This is a particularly important advantages for micro parts;

3) Flame retardant series can be widely used in electrical components industry. They also have the highest t UL flame temperature index among the thermoplastic polyester except the excellent electrical performance

4) PET is the green environmental protection material, recyclable and degradation. |

2. PET Replace PBT

PET may replace PBT because it has a close molecular structure and related properties with PBT. Compared with PBT, PET has advantage: |

改性PET的优势:

1)lower cost

2)Higher mechanical properties

3)Higher thermal resistance

4)Lower shrinkage

|

|

|

|

3. Common application of modified PET

Application of modified PET in the automotive industry

Application of modified PET in the Electrical and electronic industry

Application of modified PET in the Consumer goods

改性PET在汽车上的应用(2)

结构件和功能件

|

|

| 后挡风玻璃雨刮器臂 |

线圈骨架 |

|

|

|

| 电机外壳 |

制动助力器及阀体 |

点火线圈 | 改性PET在汽车上的应用(3)

结构件和功能件

|

|

| 反射镜电机壳体 |

汽车天窗框 |

|

|

| 汽车电器接插件 |

汽车转向盘角度感应器壳体 | 改性PET在电子电器上的应用(4)

改性PET在日用消费品上的应用(5)

|

|

| 电熨斗底板 |

散热器风扇 |

|

|

|

| 节能灯具灯头基座 |

直发器外壳 |

烤面包机外壳,烤箱把手 |

|

| |

|

4. What is the main application field of 4 modified PET? What is the demand characteristics of the material?

1. Automotive industry

1) Application: Decoration loop of car lamp. Front crossbeam of sunroof, brake / clutch system, air conditioning vents, sensor, motor shell, connectors, ignition coil, tube wiring harness

2) The demand characteristics:

.Water resistance, alkali, acid, oil, excellent machinability, and mold tolerance

.Excellent dimensional stability.

.Excellent low temperature performance.

.Strength and toughness, no floating fiber surface

.Good flowability and low shrinkage

2. Electrical and electronic industry

1) Application: The coil frame, connector, cable socket, adapter and electrical housing

2) The demand characteristics:

.Excellent heat resistance.

.High strength and modulus.

.High heat resistant, facilitate welding operation

.Constant electrical properties in broad temperature and frequency range

.Excellent dimensional stability.

.Keep well in the wet environment.

3. Consumer goods

1) Application: electric iron, hair straightener, energy saving lamp, switch, radiator fan

2) The demand characteristics:

.Excellent flame retardant, UL94 V0 level

.High heat resistant, facilitate welding operation

.Excellent mechanical properties, especially with high rigidity and hardness

.Heat resistance, yellowing resistance, thermal deformation temperature can reach 220 ℃

.Good gloss in surface, free injection

.Good thermal stability, low swelling and shrinkage

.Constant electrical properties in broad temperature and frequency range

.The excellent dimensional stability, maintain excellent physical properties in the humid environment |

|

5. What is the injection processing conditions of modified PET?

|

Items |

Units |

Typical Values |

|

Drying Temp |

℃ |

120~150 |

|

Drying Time |

h |

3~6 |

|

Molding Temp |

℃ |

250~280 |

|

Mould Temp |

℃ |

50~100 |

|

Injection Speed |

- |

Moderate to high | |

|

6. What is non-woven fabric? What is it used for?

Non-woven fabric was not formed by weaving or spinning, we simply arrange short textile fibers, or filament fibers directly or randomly to form a fiber network structure, and use mechanical, thermal or chemical methods to stick the fibers together. By using polymer pellets, short fibers or filament fibers and treat them through a variety of methods and consolidation technologies ,the new fiber products was flat structured, soft and breathable.

It is simply like this: it is not formed by wovening or knitting fibers together, but bond fibers together directly through the physical method, so when you get your fusible interlining on your clothes,you will not find thread ends on it. Non-woven fabric breakthroughed the traditional principles of spinning, and has adventages as short process, high production speed, high output, low cost, wide usage, multi-sources of raw materials and so on.

The main usages of non-woven fabric:

(1) Medical and healthy using: surgical gowns, protective clothing, disinfection pack cloth, masks, diapers, women’s sanitary napkins, etc.

(2) Family decorative using: Wall coverings, tablecloth, bed sheets, bedspread, etc.

(3) With the fitted using: lining, fusible interlining, flakes, stereotypes cotton, various synthetic leather base cloth, etc.

(4)Industrial using: filter materials, insulation materials, cement sack, geotextile fabric, coated fabrics, etc.

(5)Agricultural using: crop protection cloth, seedling cloth, irrigation cloth, heat preservation curtain, etc.

(6)Other using: Space cotton, thermal insulation materials, acoustic insulating material,oil sorbent mat, cigarette filters, tea bags, etc. |

|

7. The characteristics definition and usage classification of non-woven fabric

Durability, one-off. Insulation, electrical conductivity. Softness, stiffness. Fine,dilatability.

Isotropic, anisotropy. Filterability, breathable and waterproof. Elastic property, Stiffness

Light, loose, warm. Thin as onion skin, thick like a carpet. Waterproof and breathable.

Ironing, sewing, molding fomation. Flame-retardant, antistatic. Water permeable, waterproof, wearable, napping property.

Fold resistance, high elasticity, high moisture, waterproof.

Medical and health care: surgical gowns, caps, hood, gypsum absorbent cotton, women’s sanitary napkins, baby diapers, wet f ace towels, sanitary underpants, dust cover. |

|

8. Melt blown nonwoven process

熔喷无纺布的工艺过程:聚合物喂入---熔融挤出---纤维形成---纤维冷却---成网---加固成布。

熔喷非织造布技术的发展——双组份熔喷技术

进入21世纪以来,国际上熔喷非织造布技术的发展突飞猛进。

美国Hills公司和Nordson公司较早就开发成功双组分熔喷技术,包括皮芯型、并列型、三角形等多种,通常纤维纤度接近2μ,熔喷喷丝组件的孔数可以达到每英寸100孔,每孔的挤出量可达到0.5g/分。

皮芯型:可使非织造布达到手感柔软,可以做成同心、偏心、异形的产品。一般廉价材料做芯,昂贵的、具有特殊或所需性能的聚合物为外皮层,如芯为聚丙烯,外皮为尼龙使纤维具有吸湿性;芯为聚丙烯,外皮为可粘接用的低熔点聚乙烯或改性聚丙烯、改性聚酯等。对炭黑类导电纤维,则将导电芯包裹在里面。

并列型:可使非织造布具有良好的弹性,通常是由两种不同聚合物,或不同粘度的同种聚合物做成并列型双组份纤维,利用不同聚合物不同的热收缩性可做成螺旋式卷曲纤维。例如3M公司开发了熔喷PET/PP双组份纤维的非织造布,由于收缩不同,形成螺旋卷曲性,使非织造布具有极好的弹性。

末梢型:这是在三叶型、十字型和末梢复合另一种聚合物,如做抗静电、导湿、导电纤维时可以在顶尖上复合上导电聚合物,既可导湿、又可导电、抗静电,而且节省了导电聚合物用量。

微细旦型:可以采用橘瓣形、条形剥离型组件,也可以是海岛型组件。用两种不相容的聚合物剥裂做成超细纤维网,甚至纳米纤维网,如Kimberly-Clark研制的剥裂型双组份纤维,就是利用两种不相容聚合物做成的双组份纤维在热水中不到一秒钟,两种聚合物就可以完全剥离的特点做成超细纤维网。海岛型的则要把海溶去,得到微细的岛纤维网。

混合型:是将不同材料、不同颜色、不同纤维、不同截面形状,甚至和皮芯并列纤维混合的既有共纺,又有双组份纤维的纤维网,使纤维具有所需要的各种性能。这类熔喷双组份纤维非织造布或混合纤维非织造布和一般熔喷纤维制品相比能进一步改进过滤介质的过滤性,并使过滤介质具有抗静电性、导电性、吸湿性、增强的阻隔性等;或使纤维网的粘结性、蓬松性、透气性提高。

双组份熔喷纤维可以补充单一聚合物性能的不足,如聚丙烯比较便宜,但如用于医卫材料,它却不耐射线照射,这样可以聚丙烯为芯,在其外层选择适当的耐辐射聚合物包裹在外面就可以解决耐辐射的问题。从而可以使产品价格便宜,又能完成功能要求,如在医疗领域可用于呼吸系统的热和湿的交换器,可提供合适的类似天然的热和湿度。它具有质轻、用可弃或便于消毒、价格便宜,还可起到除去污染物过滤器的附加作用。它可由两种均匀混合的双组份熔喷纤维网组成。采用皮芯型双组份纤维,芯子为聚丙烯,皮层为尼龙。双组份纤维亦可采用异形截面,如三叶形、多叶形,使其表面积更大,同时还可以在其表层或叶尖部分采用能提高过滤性能的聚合物。烯烃类或聚酯类熔喷法双组份纤维网可以做成柱形液体和气体过滤器。熔喷双组份纤维网还可用于香烟过滤咀;利用芯吸效应做高档吸墨水芯子;保液和输液的芯吸棒等。

熔喷非织造布技术的发展——熔喷纳米纤维

过去开发熔喷纤维都基于Exxon的专利技术,但最近几年国际上多家公司已突破Exxon技术向更细的纳米级纤维发展。

Hills公司对纳米熔喷纤维作过很深的研究,据称已可达到产业化的阶段。其它一些企业例如Nonwoven Technologies(NTI)公司也开发了可生产的纳米熔喷纤维的工艺、技术,并已取得了专利。

为了纺制纳米纤维,喷丝孔比普通的熔喷设备上的喷丝孔要细得多,NTI可采用细小到0.0635毫米(即63.5微米)或0.0025英时,模块结构的喷丝板可组合成3米以上的总宽度。这样纺出的熔喷纤维直径大约为500纳米。最细的单纤直径可达200纳米。

纺制纳米纤维的熔喷设备由于喷孔小,如不采取措施,产量必然大大降低,因此NTI采取加大喷丝孔的孔数,每个喷丝板有3排甚至更多排的喷丝孔。将很多单元组件(根据幅宽而定)组合在一起,在纺丝时产量便可大幅提高。实际情况是当采用63.5微米孔眼时,单排每米喷丝板的孔眼数为2880个,如采用三排,则每米喷丝板的孔眼数可达到8640孔,这样其产量就可与纺制普通熔喷纤维相当。

由于高密度孔的薄型喷丝板价格昂贵,且很易碎裂(在高压强下受热裂开),因此各公司都开发了粘结新技术以增强喷丝板的牢度,使之不因高压强的情况下渗漏。

目前纳米熔喷纤维可以用作过滤介质,可以显著提高过滤效率。也有资料显示:由于纳米级熔喷非织造布中的纤维更细,可以采用更轻克重的熔喷布与纺粘复合,仍可承受同样水头的压力,而其制成的SMS类产品可以减少熔喷纤维所占的比重。 |

|

9. Support Service/FAQ

1)Spinning uneven

2)Mesh clogging

3) Crystal pot

4) Hydrostatic pressure is not enough |

| |

| |

| | |

|