|

|

You are here:  Home > Application Center > Case Share Home > Application Center > Case Share |

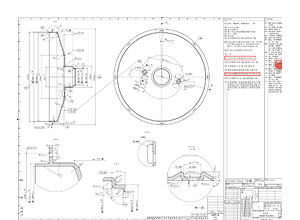

| 1£®Plastic steel solution of G7130ZL |

At present£¬vacuum booster master cylinder housing is molded by stamping DC04 steel sheet,which surface is used by cathodeelectrophoresis coating for corrosion. However, this processing cycle is very long and high cost scale¡¢weight doesn¡¯t conform to the lightweight, environmental protection, recyclable development trend of modern automobile. Under this circumstances, clients put forward the special demand for the replacing from the traditional steel to the nonmetallic materials and we give the project from PP, PA to modified PET. Final success is the product G7135ZL, which help them 5% reduction in costs and 10% reduction in weight. At present£¬vacuum booster master cylinder housing is molded by stamping DC04 steel sheet,which surface is used by cathodeelectrophoresis coating for corrosion. However, this processing cycle is very long and high cost scale¡¢weight doesn¡¯t conform to the lightweight, environmental protection, recyclable development trend of modern automobile. Under this circumstances, clients put forward the special demand for the replacing from the traditional steel to the nonmetallic materials and we give the project from PP, PA to modified PET. Final success is the product G7135ZL, which help them 5% reduction in costs and 10% reduction in weight. |

The circumstance condition entironment of vacuum booster master cylinder:

1) Temperature requirements: vacuum booster master cylinder is in the engine compartment, so the use of the environment is from 120¡æto -40¡æ;

2) Waterproof requirements: it can¡¯t be affected in the 100% humidity and salt fog environment and also can meet the requirements of product performance.

3) Strength requirements: the housing nust bear 1 atmospheric pressure (1bar) and must ensure that no deformation in the actual use.

4) The forming requirements: the wall thickness of this housing is around 1mm,which need the stability for easy injection and maintain the size in the use of environment.

5) Anti-fatigue requirement: this housing need good sealing performance and have a certain degree of impact resistance ability which can still ensure good sealing performance after undercertain bump. In addition, the anti-fatigues performance must also meet the requirements of more than 15 years¡¯ life, especially at high temperature condition.

6) Medium resistance requirements: this housing must withstand the brake fluid, engine oil, gear oil, gasoline / diesel etc. |

|

G7130L has the following characteristics:

1) Good dimensional stability and requirements the meet of the temperature -40~120 ¡æenvironment and vacuum condtion

2) Resistance to humidity and acid fog characteristics, oil medium resistance in the cabin;.

3) Meet the anti-fatigue test and has the properties for the resistance to aging ; |

| | |

|